About H-Mat

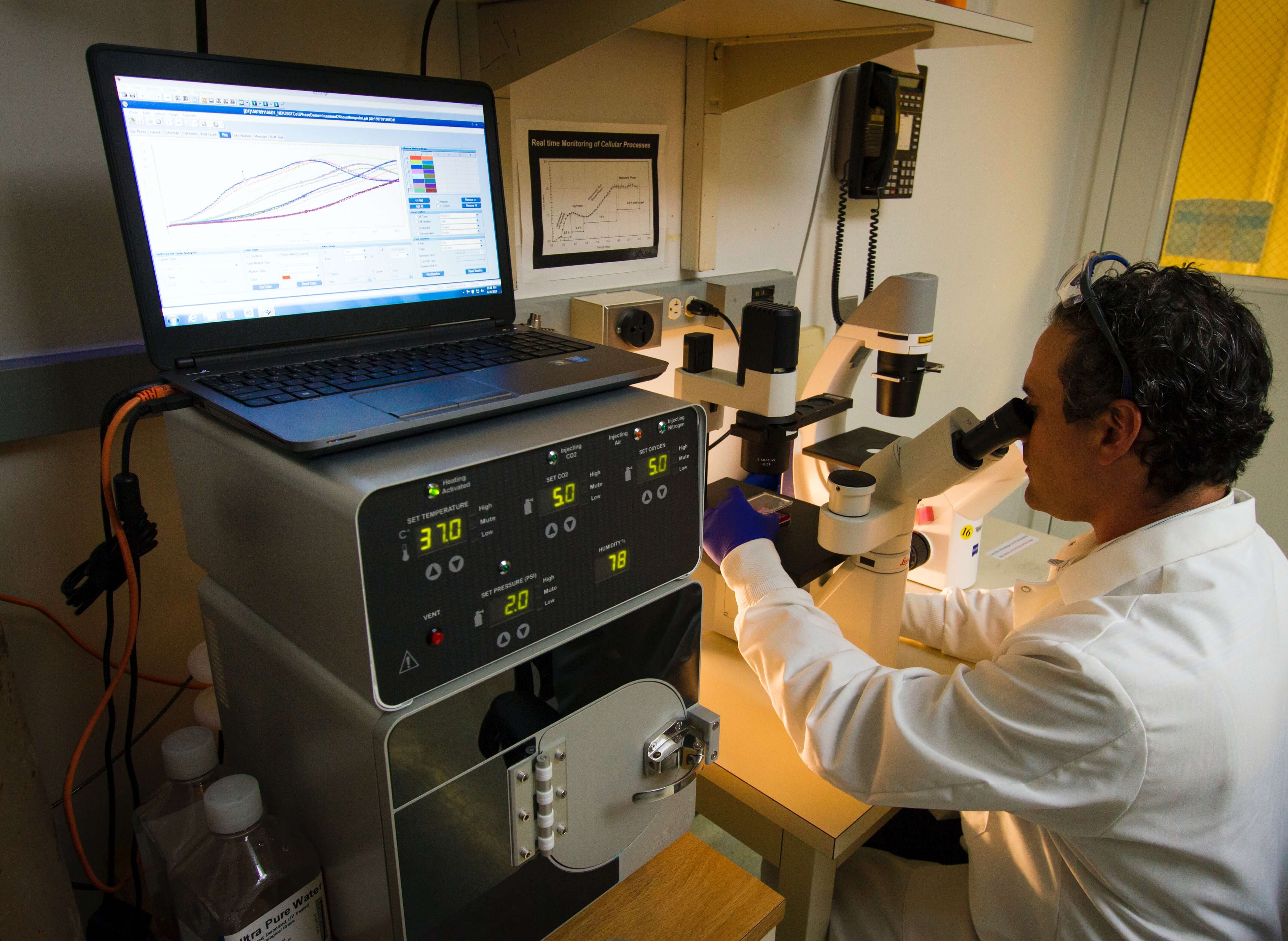

Working in collaboration with over 40 partners in industry and academia, the Hydrogen Materials Compatibility Consortium, or H-Mat, focuses on understanding the effects of hydrogen on the performance of polymers and metals used in hydrogen infrastructure and storage. H-Mat was launched in 2018 by the U.S. Department of Energy’s Hydrogen and Fuel Cell Technologies Office in the Office of Energy Efficiency and Renewable Energy.

Applications currently being studied included hydrogen blending in natural gas pipelines, hydrogen storage vessels for fueling stations and vehicles, hydrogen dispensing components (e.g. hoses, seals, nozzles), materials discovery, and accelerated test methods in hydrogen. Research activities include high-pressure testing of samples in hydrogen, multi-scale modeling of hydrogen effects, and microstructural engineering of materials to enhance resistance to hydrogen effects.

Consortium members include Sandia National Laboratories, Pacific Northwest National Laboratory, Oak Ridge National Laboratory, Savannah River National Laboratory, and Argonne National Laboratory.

Why focus on hydrogen materials compatibility?

Interest in hydrogen use is growing in many emerging applications, such as fuel cell transportation, metals refining, synthetic fuels, energy storage, and stationary power. Materials used in these demand sectors are selected based on their compatibility with hydrogen. R&D on materials compatibility with hydrogen at varying pressures, mechanical loads, and temperatures can enable components to be designed at lower cost. Research outcomes of H-Mat projects will inform industry stakeholders and the codes & standards community in the design and operation of hydrogen technologies.

Improving the reliability of materials

Reducing materials costs