R&D Activities

Research and development (R&D) activities within H-Mat include the study of metals and polymers of interest in hydrogen infrastructure and onboard fuel cell electric vehicles. For examples of recent work in these areas, please see the Hydrogen and Fuel Cells Program's Annual Merit Review and Peer Evaluation Meeting presentations covering R&D on polymers, metals of interest in pressure vessels, and metals of interest in pipelines, along with webinars on hydrogen pipeline materials and recent code modifications.

Polymers

Atomistic to micro- and macro-scale modeling of hydrogen-induced degradation of polymers to understand hydrogen transport, bubble nucleation, and hydrogen-induced degradation of polymers at multiple length scales that will thereby inform materials evaluation and design.

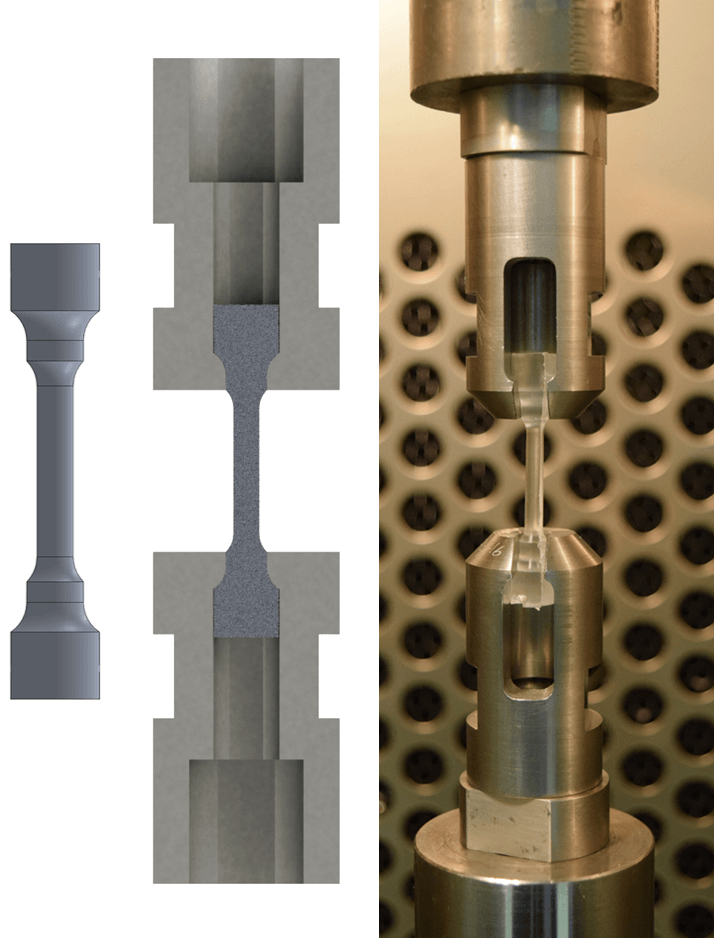

Experimental discovery of the mechanics of hydrogen-induced degradation in polymers to quantify the relationship between hydrogen pressure-temperature-time-damage and polymers by use of controlled structure morphology to inform models leading to...

Development of hydrogen-resistance polymeric formulations, modified and new materials systems with greater resistance to the environmental effects of pressure and temperature.

Metals

Quantification of hydrogen effects at microstructural length scales in austenitic stainless steels to identify governing physical processes of hydrogen embrittlement in austenitic stainless steels (e.g., for use in piping and fittings at fueling stations), leading to identification of hydrogen-resistant, high-strength ferritic steel microstructures based on that mechanistic understanding of fracture processes in ferritic steel. The goal is to significantly improve fatigue and fracture resistance of low-cost steels with tensile strength > 950 MPa in high-pressure hydrogen service.

Clarification of mechanisms of hydrogen degradation in high-strength aluminum alloys to understand the influence of water vapor on hydrogen embrittlement of high-strength aluminum alloys in order to enable the use of high-strength aluminum alloys in hydrogen systems (e.g., piping, tubing, fittings).

Development of a framework to quantify damage and crack nucleation in hydrogen environments to understand the mechanics of hydrogen-induced damage leading to crack nucleation in metals and the number of cycles required.

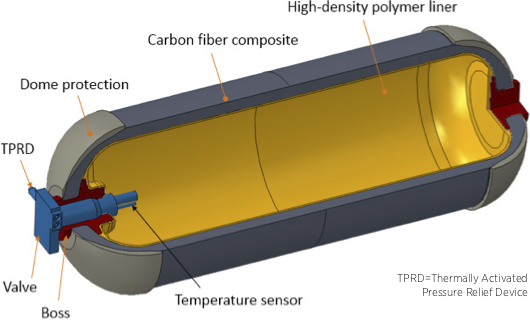

Systems

Evaluation of the behavior (e.g., fatigue life, resistance to buckling) of composite materials, austenitic steels, and weld materials in cryogenic conditions (down to 20K) to assess the viability of current and experimental materials for cryo-compressed hydrogen storage in onboard fuel cell vehicles, as well as to identify key technical metrics for viable structural materials in this application.

Assessment of the compatibility of pipeline materials with varying blends of hydrogen and natural gas Blending in Pipelines, , is support of the DOE’s HyBlend initiative, the H-Mat consortium is part of a team led by the National Renewable Energy Laboratory with over 40 industry partners, conducting R&D to enable hydrogen blending in natural gas pipelines.